Tx Tees for Beginners

Tx Tees for Beginners

Blog Article

Tx Tees for Beginners

Table of ContentsFacts About Tx Tees RevealedFascination About Tx TeesA Biased View of Tx TeesRumored Buzz on Tx TeesThe Buzz on Tx TeesThe Only Guide for Tx TeesTx Tees Can Be Fun For Everyone

Add up various other costs, like the number of energies it takes to run the store and the cost of ink and solution per design. Take the print below.The emulsion should just be a couple of cents considering that you 'd just need to coat one display for this job. So just how much should you bill per shirt to earn a profit? Generally, printers attempt to make up to 45% profit on a print work. Right here's a table to help you figure out that: complete price per item percent of wanted earnings as a decimal (example:.25 or.45) earnings made per thing per job Now let's talk concerning the earnings of DTF.

With DTF, you can publish a handful of shirts, or just one. Use the same calculator as the section above to compute just how much revenue you would certainly use DTF transfers. Contrast the prices and revenues to whichever technique talks best to your arrangement and procedure. Both screen printing and DTF have their particular niches in the world.

A Biased View of Tx Tees

The very best way to recognize? Ask around and see what print shops like yours are doing. screen printer. Attempt both out and see which you like much better

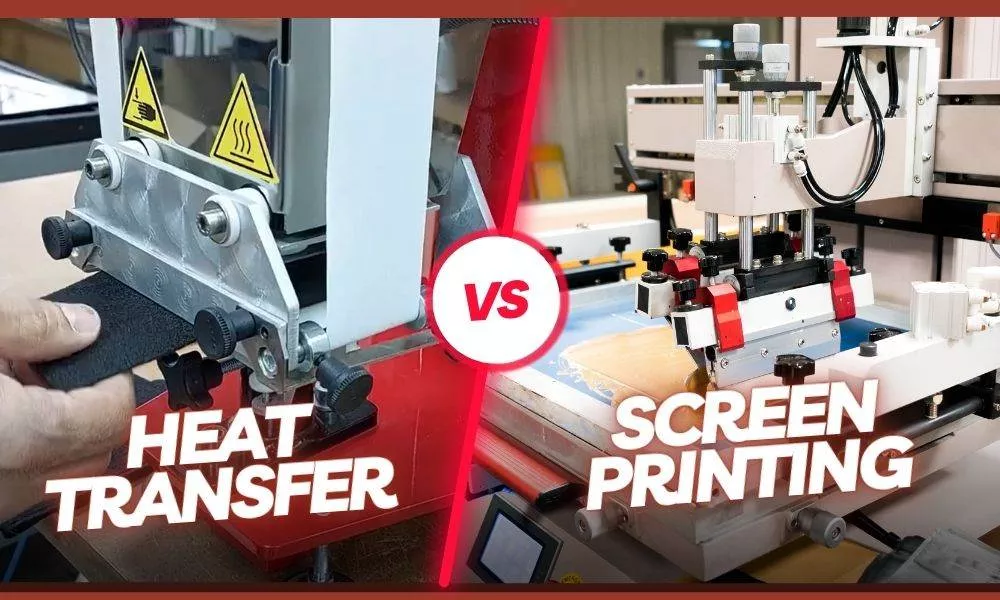

When you're picking what sort of printing approach to utilize for printing your art work designs on your garments, it is essential that you recognize the differences between these 2 techniques so you can make the most of outcomes while reducing expenses. Display printing is the most frequently utilized technique for printing designs on textiles.

DTG printing is likewise called place or straight to garment printing since it publishes only what is needed rather than making a display as screen printers do. https://www.magcloud.com/user/txtees02. Screen printing works by screen filler squeegee screen printing ink display mesh display, after that transferring the photo to garment using heat and/or pressure

The DTG printer utilizes special dye-sublimation inks that are used into a pre-designed picture by an electronic printing system. The inks enter into the material, allowing for dynamic shades and extraordinary detail. It's likewise called place or straight to garment printing because it prints only what is required rather than making a display as screen printers do.

Facts About Tx Tees Uncovered

First, it's much quicker - you can publish a fullcolor picture in mins, in contrast to hours for screen printing. Second, there's no set up time or expenses involved - you can print any type of layout you like, without having to produce a display. Third, there's no waste - since display printers screen print one style at a time, they need to evaluate each shade separately.

The paper is extremely expensive and can only be made use of once. Once it's published on, it has to be discarded. - The first acquisition rate is reduced than the upfront investment of DTG printers- You can print multi-color styles one display at once as opposed to having to publish each shade separately like DTG printing.

Examine This Report about Tx Tees

Rather of using display mesh as display printers do, dye sublimation printers use laser technology to transfer your pictures onto garments or paper. A warm process moves the dye from its solid-state straight into the gas phase which in turn fuses it onto textile substrates when they are rapidly heated up to heats under high stress.

Sublimation printing is environmentally friendly. It uses less water than screenprinting, and due to the fact that it does not include the use of harmful solvents, it's safe for all types of apparel. The dye sublimation inks are likewise odor-free when treated, unlike display printers that use harmful chemicals during the screen printing procedure that leave behind an unpleasant smell.

They additionally conserve money on expensive equipment like exposure systems considering that dye sublimation printers don't require a UV direct exposure device or a flash remedy stove that is generally used in display printing (custom t-shirt design). What is straight to garment printing (DTG Printing)? DTG printing is an electronic screenprinting process that publishes straight onto material using specialized inkjet printers

Tx Tees Can Be Fun For Everyone

DTG printing uses numerous advantages over standard screenprinting, including the ability to publish photographic high quality photos, greater shade vibrancy, and the capability to publish designs on darker fabrics. DTG printers work by warming the fabric ink until it develops into a gas. The gas then penetrates the material, bonding with the fibers to produce a permanent print.

Display printers just prepare their screen then start printing till they lack product or ink.- There is a wide variety of seasoned screen printers around the world, which can be useful for novices. - It's a slower process - display printers typically need to await the ink to dry prior to they can print the following check this color- Display printers call for hands-on labor, so there's a greater discovering contour and it takes longer to generate a premium design- Screen printing isn't as exact as DTG printing, so you might obtain some "blood loss" of shades from one part of the photo onto another otherwise done effectively.

Excitement About Tx Tees

Instead of using display mesh as display printers do, color sublimation printers use laser innovation to transfer your images onto garments or paper. A heat process moves the color from its solid-state directly right into the gas stage which subsequently fuses it onto material substrates when they are quickly warmed to high temperature levels under high stress.

Sublimation printing is eco-friendly. It makes use of less water than screenprinting, and since it doesn't entail the use of damaging solvents, it's safe for all types of clothing. The dye sublimation inks are also odor-free when healed, unlike screen printers that use damaging chemicals throughout the screen printing process that leave an unpleasant odor.

They also conserve cash on expensive devices like exposure units since dye sublimation printers do not call for a UV direct exposure device or a flash remedy oven that is normally used in screen printing. What is direct to garment printing (DTG Printing)? DTG printing is a digital screenprinting process that prints directly onto fabric utilizing specialized inkjet printers.

Indicators on Tx Tees You Should Know

DTG printing offers many advantages over typical screenprinting, including the capacity to publish photo high quality images, greater shade vibrancy, and the ability to publish styles on darker fabrics. DTG printers function by warming the fabric ink until it develops into a gas. The gas then permeates the textile, bonding with the fibers to develop a permanent print.

Report this page